Keep in mind that an undercharged battery is often caused by car accessories being left on overnight, or by a rear compartment or instrument panel compartment lamp that stays on.

When the charging system is operating normally, the charge indicator lamp will come on when the ignition switch is turned ON and will go out when the engine starts. If the lamp does not come on with the key ON you will need to check the warning light circuit or replace the bulb.

Alternatively, noise from an alternator may be caused by the following components:

- Improper routing of hoses, wiring, or shielding against the alternator housing

- A loose drive pulley

- Loose mounting bolts

- Worn or dirty bearings

- A faulty diode

- A faulty stator

- Brush/slip ring friction

Precautions

- Do not reverse the connections to the alternator.

- Do not short across, or ground any of the terminals in the charging circuit, except as directed by the instructions.

- Do not attempt to hotwire the alternator by connecting B+ voltage to any of the alternator 4-way connector terminals. Use only an approved test harness as described in these instructions.

- Never disconnect the output terminal while the alternator is operating.

- Use only approved terminal probe adapters to connect the meter leads and the jumper wires to the connector terminals. Using improper adapters will damage the terminals and cause charging system or test harness failure.

Inspection

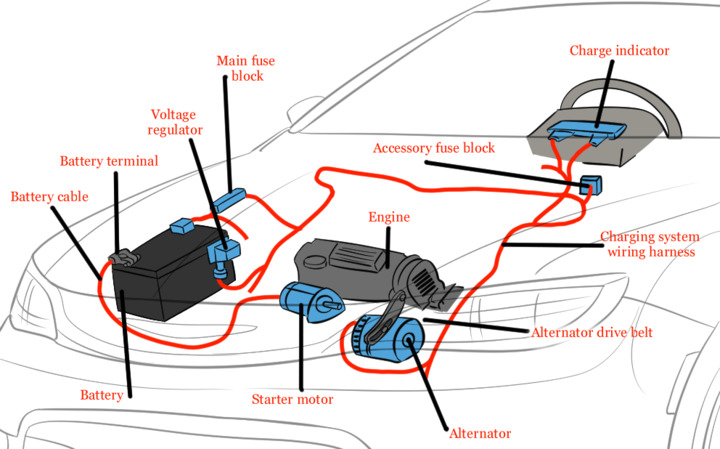

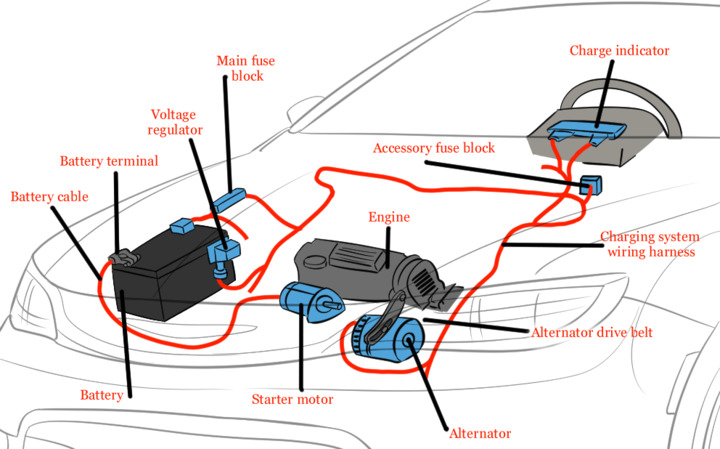

Before testing the alternator inspect the following components and conditions:

- Battery: Verify that the vehicle battery is in good condition and fully charged.

- Built-in hydrometer in the battery: The green eye must be showing in the hydrometer.

- The voltage across the battery terminals with all loads OFF should be above 12 volts.

- Verify that the battery connections are clean and tight.

- Drive belt for damage or looseness.

- Wiring harness at the alternator. Verify that the harness connector is tight and latched. Verify that the output terminal of the alternator is connected to the vehicle battery positive alternator lead.

- All charging system related fuses and electrical connections for damage or looseness.

Diagnosis

If the battery tests good but still fails to perform well, the following are some of the more common causes:

- A vehicle accessory was left on overnight

- The driving speeds have been slow with frequent stops

- The electrical load has exceeded the generator output (particularly with the addition of aftermarket equipment)

- The existing conditions in the charging system include the following possibilities:

- An electrical short

- A slipping belt

- A faulty generator

- A faulty generator voltage regulator

- The battery has not been properly maintained, including the following situations:

- A failure to keep the terminals tight

- A failure to keep the terminals clean

- A loose battery hold-down retainer

- A power failure caused by an existing mechanical condition in the electrical system, such as a short or pinched wire

- Extended vehicle storage

- Extended cranking periods due to a possible fuel or ignition system problem.

- Incorrect interpretation of the battery's built-in hydrometer

- There has been an insufficient ampere-hour charge rate for a discharged battery

- There is a continuous current draw on the battery through excessive parasitic drain

- The battery is old

Self-discharge is always occurring as a result of internal chemical reactions, even when the battery is not connected. In hot weather, this chemical reaction is increased dramatically. This is why the number of discharged batteries will increase in very hot weather.

Battery Capacity Test

To carry out this test, use a high rate discharge tester, Battery Tester, in conjunction with 73 Digital Multimeter.

- Turn the tester to the OFF position.

- Turn the multimeter selector switch to the DV volt position.

- Connect the tester and multimeter positive test leads to the positive battery post and both negative test leads to the negative battery post. The multimeter clips must contact the battery posts and not the tester clips. Unless this is done, the actual battery terminal voltage will not be indicated.

- Turn the load control knob in a clockwise direction until the ammeter reads approximately half of the cold cranking amps of the battery.

- With the ammeter reading the required load for 15 seconds, note the multimeter reading.

- If the multimeter reading is 9.6 volts at 21°C (70°F) or more, the battery has a good output capacity and will readily accept a charge, if required.

- If the voltage reading is below 9.6 volts at 21°C (70°F) and the battery is fully charged, the battery is damaged and a new battery must be installed. If you are unsure about the battery's state of charge, charge the battery.

- After the battery has been charged, repeat the Battery Capacity Test.

- If the capacity test battery voltage is still less than 9.6 volts at 21°C (70°F), install a new battery.

- If the voltage is 9.6 or more at 21°C (70°F), the battery is satisfactory for service.

- If the battery is found to be discharged only, check for a loose drive belt, loose electrical connection, charging system performance, and carry out the Battery Drain Testing.

Caution: Avoid leaving the high discharge load on the battery for periods longer than 15 seconds.

Drain Testing With Ammeter In-Line

Check for current drains on the battery in excess of 50 milliamps with all the electrical accessories off and the vehicle at rest. Current drains can be tested with the following procedure.

WARNING: Do not attempt this test on a lead-acid battery that has recently been recharged. Explosive gases can cause personal injury.

To prevent damage to the meter, do not crank the engine or operate accessories that draw more than 1O A.

Note: Many computers draw 10 mA or more continuously. Use an in-line ammeter between the battery positive or negative post and its respective cable.

- Turn the switch to mA/A dc.

- Disconnect the battery terminal and touch the probes.

- Isolate the circuit causing the current drain by pulling out one fuse after another from the fuse junction panel while reading the display. The current reading will drop when the fuse on the bad circuit is pulled.

- Reinstall the fuse and test the components (including connectors) of that circuit to find the defective component(s). Test Conclusion The current reading (current drain) should be less than 0.05 amp. If current drain exceeds 0.05 amp, a constant current drain is present. (Underhood, glove compartment and luggage compartment lamps that do not shut off properly are all possible sources of current drain.)

If the drain is not caused by a vehicle lamp, remove the fuses from the interior fuse junction panel one at a time, until the cause of the drain is located.

If the drain is still undetermined, remove the fuses one at a time at the power distribution box to find the problem circuit.

Alternator Testing

To prevent damage to the alternator (GEN), do not make jumper wire connections except as directed. Do not allow any metal object to come in contact with the housing and the internal diode cooling fins with the key on or off. A short circuit will result and burn out the diodes.

Note: Battery posts and cable clamps must be clean and tight for accurate meter indications.

- Turn OFF all lamps and electrical components.

- Place the vehicle in transmission range NEUTRAL and apply the parking brake.

- Carry out the Load Test and No-Load Test.

- Switch the Battery Tester to the ammeter function.

- Connect the positive and negative leads of the Battery Tester to the corresponding battery terminals.

- Connect the current probe to the alternator B+ output lead.

- With the engine running at 2000 rpm alternator output should be greater than as shown on the graph.

- Switch the Battery Tester to the voltmeter function.

- Connect the voltmeter positive lead to the alternator B+ terminal and the negative lead to ground.

- Turn all electrical accessories off.

- With the engine running at 2,000 rpm, check the alternator output voltage. The voltage should be between 13.0 and 15.0 volts.

|